Easy, Quick & Accurate Filter Testing

The Filter Integrity Tester is a compact standalone bench-top unit capable of fully automating the process of bubble-point testing commonly used vented & non-vented sterilizing filters used in radiopharmaceutical quality control.

The Filter Integrity Tester is designed to replace manual bench top systems or manual methods of testing sterilizing filters to enable the following.

3 Simple Steps

Step 1:

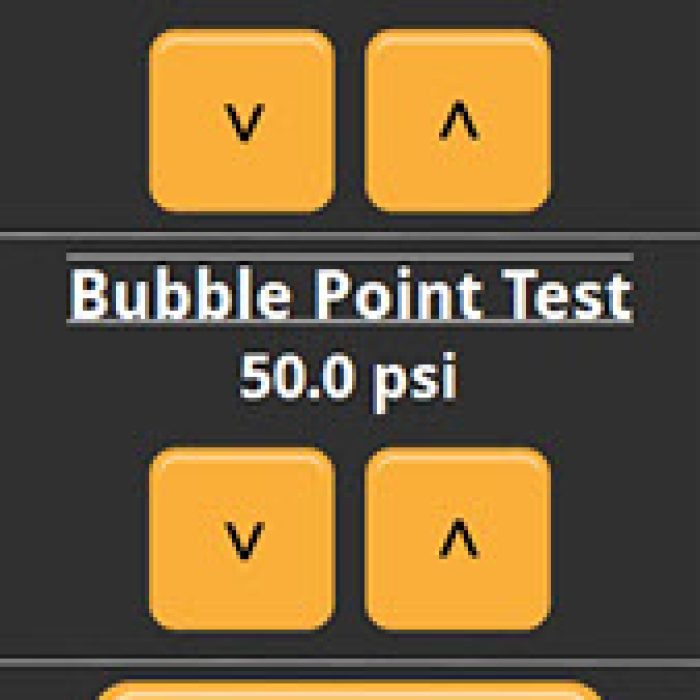

Set test pressure and test ID

Step 2:

Load solution, insert filter and test

Step 3:

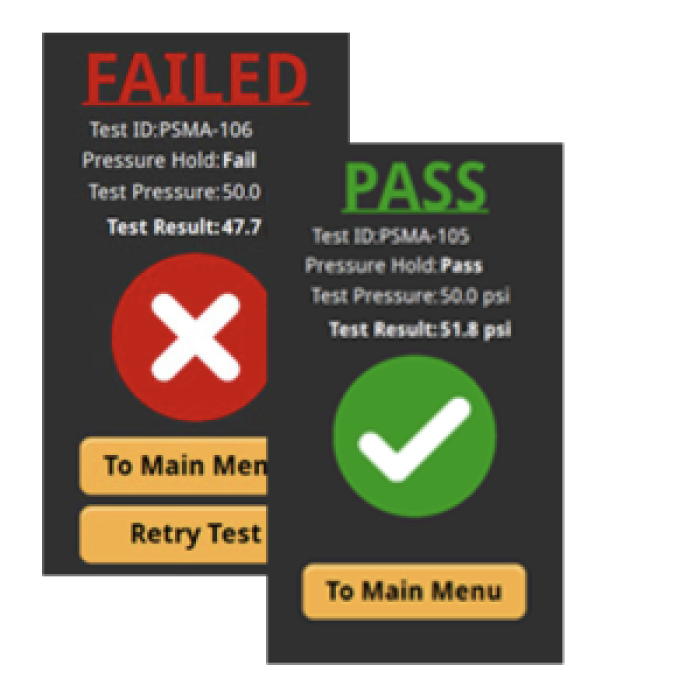

Results either pass or fail

- Select parameters

Select pressure hold test time and bubble-point pressure as per filter manufacturer specification’s along with Test ID. - Test Process:

- Wet filter

Load up to 35mL of wetting solution (usually water) into the solution reservoir. The solution will be pushed through the filer to wash off residual product which could alter the bubble point.This step standardises testing and performs the process as per the filter manufactures recommended test procedure.

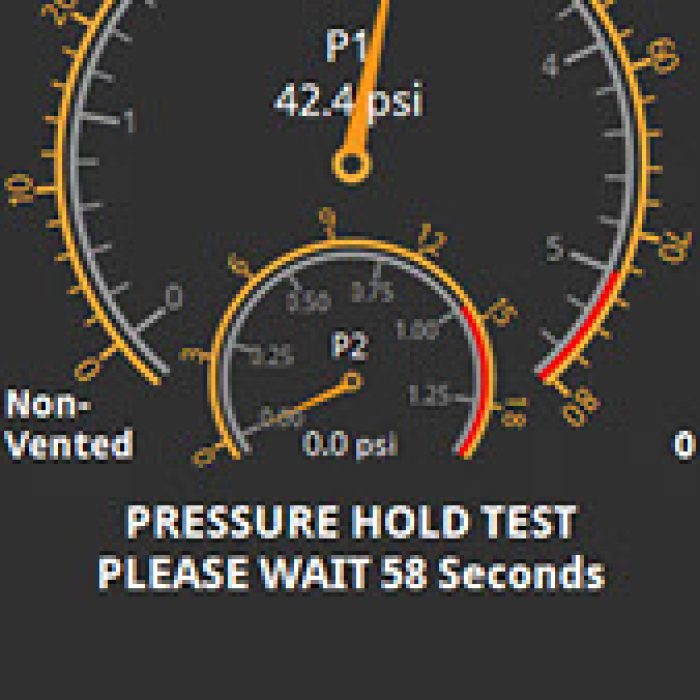

- Pressure hold test

The test is started by pressure being slowly increased up to 80% of the bubble point pressure for a specific amount of time in which the system checks that there are no bubbles/pressure increase on the outlet of the filter. - Bubble Point Test

After the pressure hold test the Filter Integrity Tester slowly increases the pressure to check the bubble point. The Filter Integrity Tester will then record the pressure when bubbles appear/pressure increases on the filter outlet to determine the bubble point pressure.

- Wet filter

- Results

Once the test is complete the filter integrity will display a pass or fail screen with the pressure result.

FILTER INTEGRITY TESTER TECHNICAL SPECIFICATIONS

Test Method

Sterile Filters

Filter Wetting

Gas Supply

Power Supply

Dimensions & Weight

•Non-destructive true bubble-point using calibrated pressure sensors

• Non-vented and vented up to 35mm diameter

• Yes, by loading internal 40mL reservoir with desired solution volume

• Any gas 5-8 bar (73-116 psi), 1/8″ OD push in connection

• 110 V-240 V, 50/60 Hz

• w150 x h235 x d150 mm (w5.9″ x h9.3″ x d5.9″), 1.9 kg (4.2 lb